Labor shortages cost U.S. manufacturers billions annually. According to NAM, 77% of manufacturing leaders list workforce challenges as their top concern, and unplanned downtime can cost plants $22,000 per minute on average. For many facilities, labor contingency planning has become as critical as equipment maintenance or supply chain forecasting.

From a psychological standpoint, workforce disruptions create stress, uncertainty, and decreased morale among employees. Research in organizational psychology shows that unexpected staffing gaps increase cognitive load on managers, lead to burnout among remaining staff, and reduce overall job satisfaction. When people feel overworked or unsupported, errors, accidents, and absenteeism rise.

To reduce this operational and emotional strain, manufacturers increasingly rely on contingent staffing, just-in-time staffing, and emergency staffing solutions to stabilize production. In this guide, we’ll break down the real costs of delays, explore how contingency labor supports production continuity, and outline practical steps to build a flexible, resilient workforce strategy that protects both operational performance and employee well-being.

1. The True Cost of a 24 Hour Delay in Production Continuity

A single day of unplanned downtime can trigger cascading consequences: idle production lines, missed orders, overtime, expedited shipping, quality issues, and loss of customer confidence. Studies suggest that unexpected delays may increase operational costs by up to 20%, while idle lines can amount to several thousand dollars per hour depending on industry and scale .

In lean and just‑in‑time manufacturing environments, such disruptions ripple through supply chains and contract obligations, damaging margins, timelines, and long-term reputation. This is why plant managers increasingly incorporate contingency workforce planning to prevent prolonged downtime and avoid costly production bottlenecks.

2. How Contingency Labor Can Save Q3 and Q4 Targets Through Just-in-Time Staffing

Post‑pandemic labor scarcity has pushed temp workers to represent up to 30% of plant workforce in many sectors, particularly when permanent workers are in short supply. Just‑in‑time staffing solutions ensure that plants can respond rapidly to spikes in demand without overburdening existing employees or committing to long-term hiring costs.

- Rapid workforce scale‑up when demand spikes in Q3/Q4

- Reduced hiring lead times via pre‑vetted temp staffing agency worker pools

- Cost efficiencies: agencies often deliver up to 15–20 % savings through strategic sourcing and temp‑to‑perm conversions

- Talent evaluation opportunity: temp labor permits real‑time performance assessment before full-time hiring decisions

This blend of speed, flexibility, and cost control helps you hit targets without compromising safety, quality, or compliance.

3. Staffing for Flexibility: Cross-Training & Temp Solutions From a Temp Staffing Agency

To maintain agility, adopt a hybrid approach:

- Cross-training existing staff strengthens operational redundancy and improves workforce flexibility, helping reduce job gaps. Studies show cross-trained teams improve productivity and engagement by ~10%.

- Temporary and contract labor fills short-term peaks without long-term costs. While temp staffing may carry slightly higher overhead per hour, overall it often reduces administrative and benefit expenses tied to permanent hires .

Blending internal capability with temporary workforce solutions reduces burnout, enhances production resilience, and positions the plant to scale talent in sync with real-time operational needs.

4. Building a Roster of Standby Talent for Workforce Capacity Expansion

Don’t wait for a crisis, build a pool of standby talent in advance:

- Track performance ratings, certifications, attendance, and reliability.

- Maintain relationships with high-performing temps, gig workers, retirees, or permatemps who understand your processes .

- Prioritize repeat engagement workers who’ve used your environment are more productive, safer, and require less training.

A strong standby roster minimizes onboarding delays and supports production continuity during high-pressure quarters when rapid staffing becomes essential.

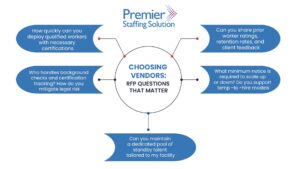

5. Choosing Vendors: RFP Questions That Matter for Contingent Staffing Partners

When evaluating staffing partners, plant managers should apply a more rigorous, strategic approach — similar to assessing operations consulting firms or operational excellence consulting firms for process improvement work.

- Response speed & onboarding: “How quickly can you deploy qualified workers with necessary certifications?”

- Performance transparency: “Can you share prior worker ratings, retention rates, and client feedback?”

- Compliance rigour: “Who handles background checks and certification tracking? How do you mitigate legal risk?”

- Scalability flexibility: “What minimum notice is required to scale up or down? Do you support temp‑to‑hire models?”

- Preferred pool management: “Can you maintain a dedicated pool of standby talent tailored to my facility?”

These questions ensure alignment, reduce compliance gaps, and validate whether a partner can truly support surge staffing and large-scale contingent workforce needs.

6. Risks & Cons to Mitigate in Contingency Workforce Planning

Even the best-labeled strategy requires oversight:

- Safety concerns: Contingent workers face higher rates of injury, often 3‑4× more than regular staff, due to less familiarity with site hazards and limited training .

- Integration issues: Temps unfamiliar with internal culture may disrupt teamwork or communication.

- Hidden costs: Frequent rotation or high turnover increases training overhead and reduces consistency.

Counteract these risks with structured safety orientation, mentorship pairings, and robust retention planning.

7. Integrating Contingency Labor Into Risk & Cost Planning for Manufacturing Leaders

Effective contingency planning isn’t just workforce, it’s financial strategy:

- Incorporate labor contingency as part of your broader contingency cost reserves. Variable costs like labor, training, expedited logistics, and overtime must be calculated upfront to prevent budget overruns .

- Leverage cost‑estimation software that models “what‑if” scenarios, simulating labor shortages or supplier delays, to allocate contingency funds with precision rather than blunt percentages .

- Conduct business impact analysis (BIA): identify peak vulnerability periods (e.g. end-of-quarter surges), forecast costs of delays (lost revenue, expedited shipping, overtime), and map recovery strategies accordingly .

This turns contingency labor into a dynamic, data-driven component of your broader plant workforce strategy.

Conclusion: Why Labor Contingency Planning Is Essential for Modern Manufacturers

Labor contingency planning is not optional, it’s essential. Whether you face sudden demand surges, workforce attrition, or seasonal cycles, a well-designed approach cushions your operations and preserves profitability in Q3 and Q4.

Ready to Strengthen Your Production Continuity With Contingent Staffing Experts?

At Premier Staffing Solution, we offer strategic, scalable staffing programs built for manufacturing resilience:

- Rapid deployment of vetted contingent staffing teams

- Cross‑training frameworks for internal flexibility

- Standby talent pools for production continuity

- Vendor evaluation tools and RFP guidance ensuring alignment with safety, compliance, and performance goals

Contact us today to schedule a consultation and design your customized contingency workforce blueprint, protect your Q3 and Q4 production goals without compromising quality or compliance.

FAQs

Q1: How do I quantify the cost of a 24‑hour production delay?

Evaluate lost production (units × margin), overtime needed to recover output, expedited freight, penalties for late delivery, and downstream costs. Many operations teams also consider staffing gaps and the need for contingency workforce planning to prevent future losses.

Q2: When is temp labor most effective?

Temp labor is especially valuable during seasonal surges, unexpected absences, rapid ramp-ups, or periods when permanent hiring lags behind operational needs. Leveraging a temp staffing agency helps maintain workforce agility without committing to full-time overhead.

Q3: What safety protocols should be used with contingent workers?

Both host employers and staffing partners share OSHA/NIOSH responsibilities. Provide thorough orientation, assign mentors, and establish recurring check-ins. Facilities using just-in-time staffing or surge staffing benefit from structured safety integration to minimize incident rates.

Q4: How does cross‑training complement temp strategies?

Cross-training strengthens internal flexibility, improves productivity, and reduces reliance on external labor. When paired with temporary workforce solutions, it creates a hybrid model that stabilizes production during demand spikes or workforce shortages.

Q5: How often should contingency plans be updated?

Plans should be updated annually and before high-demand cycles. Major staffing, equipment, or supply chain changes also require reviewing your strategy for production continuity and labor risk mitigation.